Mechanical Vapour Recompression Evaporator

Mechanical Vapour Recompression (MVR) Evaporator

The Mechanical Vapour Recompression (MVR) Evaporator is an energy-efficient evaporation system that reuses the vapor generated during evaporation as a heating medium. Widely used in Zero Liquid Discharge (ZLD) systems, the MVR evaporator reduces operating costs by minimizing the need for external steam. It is suitable for treating high TDS wastewater in industries such as textiles, chemicals, pharmaceuticals, and power plants.

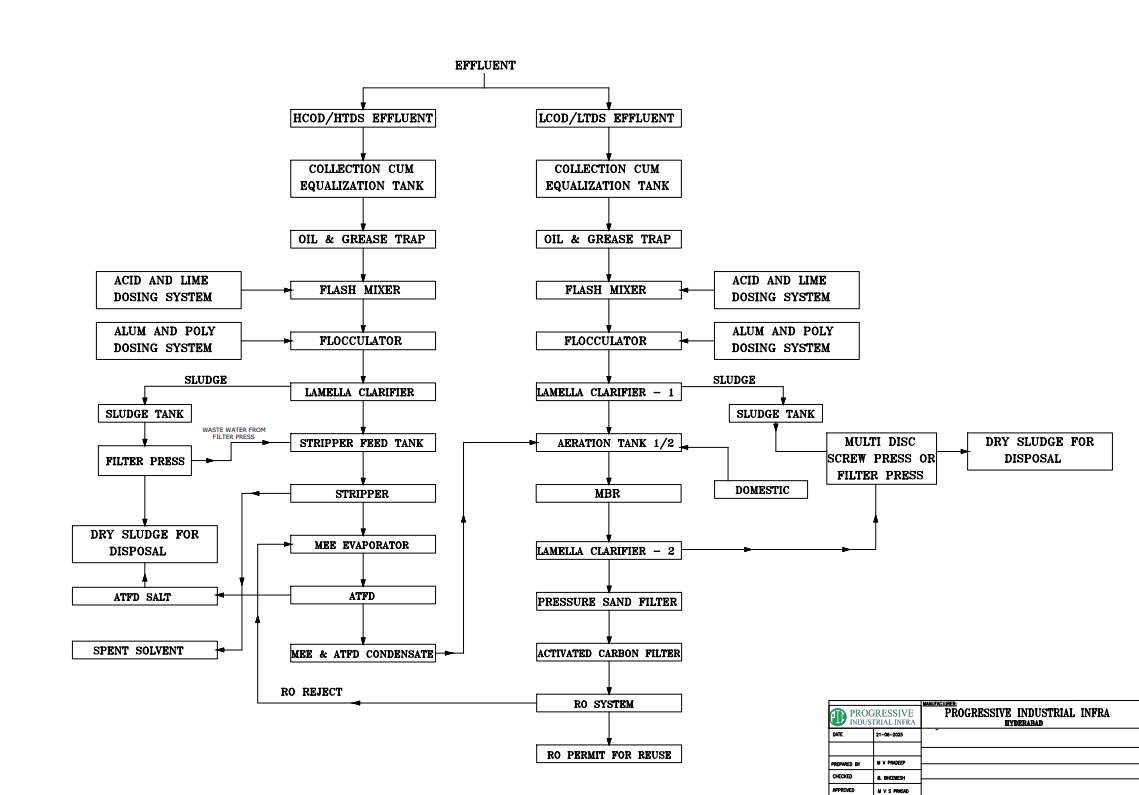

MVR Evaporation Process Diagram:

*Illustrative flow of vapour recompression and condensate recovery.

Key Features:

- Low operating cost through energy reuse

- High thermal efficiency with minimal utility consumption

- Modular design suitable for high TDS brine

- Minimal fouling and low maintenance frequency

- Optional integration with ATFD, crystallizer, or polishing unit

Applications:

- Zero Liquid Discharge (ZLD) projects

- Textile and dye wastewater

- Pharma and chemical effluent treatment

- Power plants, distilleries, and fertilizer units

Industry Standards:

- Compliant with CPCB / SPCB discharge guidelines

- Manufactured as per ASME / IS / TEMA standards

- Quality assurance under ISO 9001:2015

- Meets norms for condensate recovery & environmental compliance

How We Deliver:

- On-site effluent analysis and feasibility check

- Custom engineering and heat/mass balance calculations

- 3D design, fabrication, and quality checks

- Installation supervision and trial run at client site

- Commissioning, handover, and performance guarantee

MVR Unit Installed at an Industrial ZLD Facility:

Need a highly efficient evaporation system?

Our MVR Evaporators are designed to optimize performance and reduce utility costs. Contact our expert team for a tailored solution for your project.