Agitated-thin-film-dryer

Agitated Thin Film Dryer (ATFD)

The Agitated Thin Film Dryer (ATFD) is an advanced drying system used to concentrate and dry high-solid, viscous, and heat-sensitive liquids into powder or flakes. In wastewater and effluent treatment systems, ATFD is typically used for the final stage to achieve zero liquid discharge (ZLD) by converting slurry into dry solids.

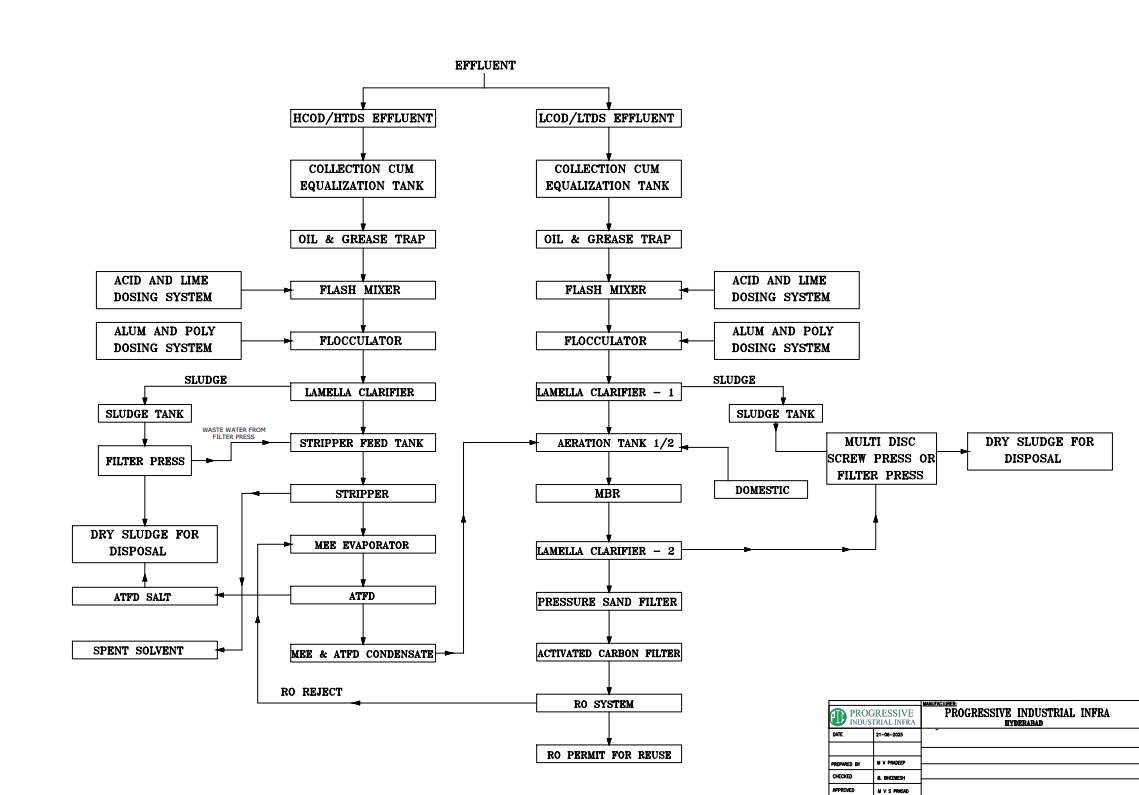

ATFD Process Flow Diagram:

*Typical process flow of an Agitated Thin Film Dryer in a Zero Liquid Discharge system.

Key Features:

- Handles high-viscosity and high-solid content feed

- Stainless steel or alloy steel contact parts

- Available in steam, hot oil, or electric heating models

- Continuous operation with high heat transfer efficiency

- Minimal space requirement and low energy consumption

Applications:

- Zero Liquid Discharge (ZLD) systems

- Chemical and pharmaceutical industries

- Dye and pigment wastewater treatment

- Food and nutraceutical industries

Industry Standards:

- Design in compliance with ASME / IS standards

- Manufactured under ISO 9001:2015 quality system

- Meets Zero Liquid Discharge (ZLD) regulatory norms

- Corrosion-resistant material as per CPCB/CREP guidelines

How We Deliver:

- Requirement analysis and feed sludge testing

- Custom design with thermal calculations

- In-house fabrication and quality testing

- On-site installation and commissioning

- Performance guarantee and long-term AMC support

Real-Time Installation at ZLD Facility:

Looking to implement Zero Liquid Discharge?

Our high-performance ATFDs are designed to deliver efficient drying and reliability. Get in touch for a complete solution tailored to your plant.

Get a quote