Forced circulation evaporator

Forced Circulation Evaporator (FCE)

A Forced Circulation Evaporator (FCE) is designed to concentrate high-solid or crystallizing solutions by maintaining high liquid velocities through tubes, reducing fouling and deposition. In water treatment, FCEs are ideal for treating complex effluents and brines in Zero Liquid Discharge (ZLD) systems. The liquid is circulated using a high-capacity pump through a heat exchanger and into a separator, where the vapor is flashed off.

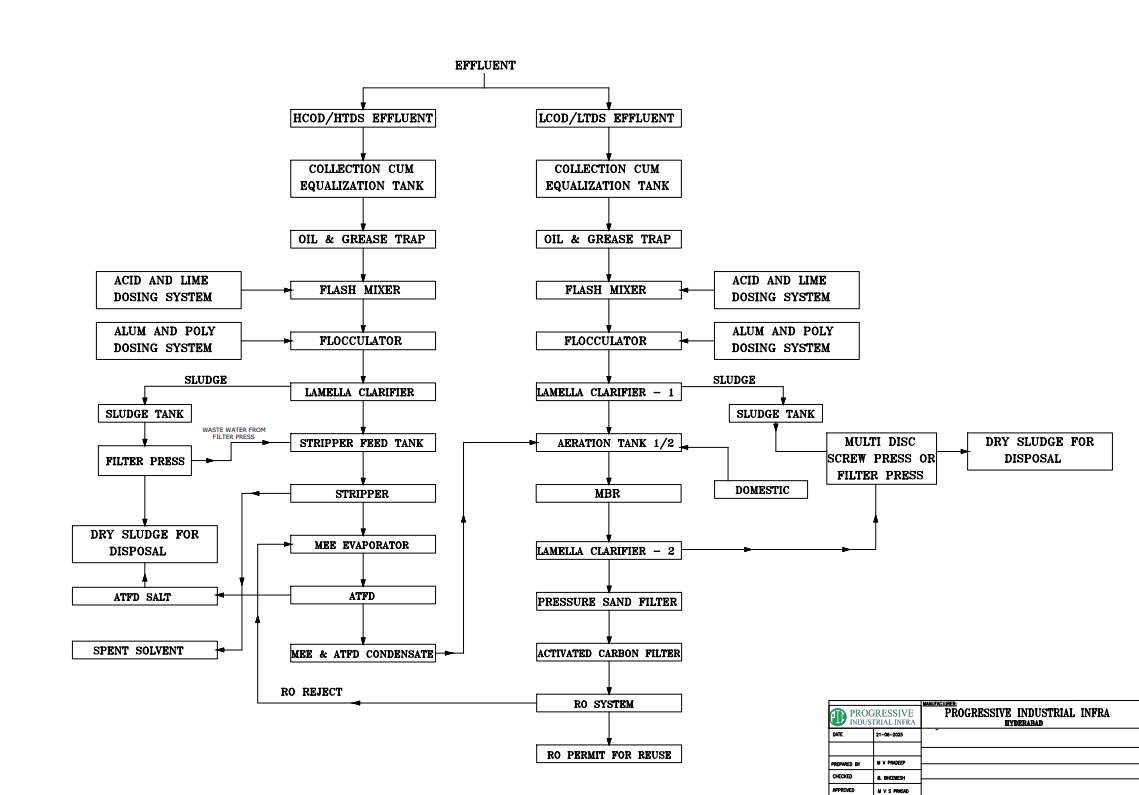

System Diagram:

*Schematic flow of feed circulation, vapor separation, and condensate recovery.

Key Features:

- Handles high TDS and high viscosity effluents

- Prevents scaling and fouling through turbulent flow

- Low maintenance and high operational reliability

- Ideal for use before crystallization or ATFD units

- Available in single and multiple effect configurations

Applications:

- Zero Liquid Discharge (ZLD) systems

- Textile, dyeing, and pharma industries

- Desalination and high-salinity wastewater treatment

- Brine and slurry concentration prior to drying

Industry Standards:

- Manufactured as per ASME / TEMA / IS codes

- Meets CPCB / SPCB discharge and reuse guidelines

- Designed under ISO 9001:2015 quality system

- Vapor condensers and piping follow GMP / cGMP as needed

How We Deliver:

- Initial effluent study and design customization

- Thermal and mechanical design with CFD support

- Fabrication, NDT testing, and quality validation

- On-site erection, utility integration, and trial runs

- Operator training, handover, and documentation

Installed FCE at Industrial Client Site:

Need a reliable solution for effluent evaporation?

Our Forced Circulation Evaporators are built for robust performance in tough industrial conditions. Contact us today to get a custom quote tailored to your wastewater challenges.